Uni-Base universal titanium bases allow the use of a fully digital CAD/CAM design and production process as well as conventional workflow. The Uni-Base AN bases allow the design of an angled screw channel and placing the screw access hole in the ideal position in the crown.

Uni-Base bases have been developed with an optimized abutment shoulder respecting an optimized gingival emergence profile. The robust base design is optimized for milling processes. Strong retention elements ensure secure bonding and reliable fixation of the restoration. CAD libraries for Uni-Base and Uni-Base AN, including libraries for manually shortened variants, are available for software from exocad, 3Shape, and Dental Wings at www.lasak.com.

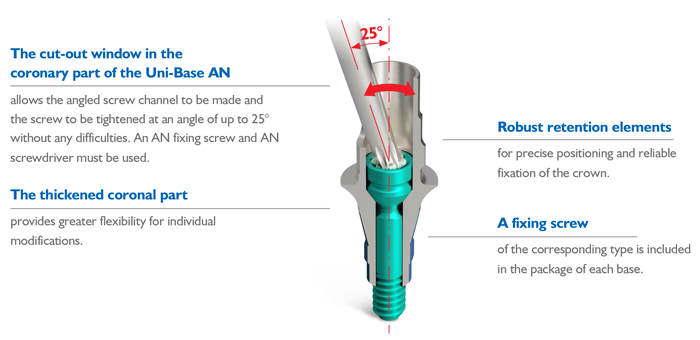

Angulated screw channels

The Uni-Base AN universal titanium bases allow the design of an angled screw channel and placing the screw access hole in the ideal position in the crown. This provides even more flexibility and efficiency in the design of implant-supported prosthetic restorations.

BioniQ AN/tx1.9 screwdriver and fixing screw

Uni-Base AN bases are delivered with a dedicated BioniQ AN/tx1.9 fixing screw. The green screws are intended for the blue QR prosthetic platform, and the silver screws with green heads for the yellow QN prosthetic platform. The BioniQ AN/tx1.9 screwdriver must be used for these screws. As an antirotation element, instead of the usual hexagon, a hexalobular is used, thanks to which the screwdriver can be used at an angle of up to 25°.

Fully digital or conventional workflow

Uni-Base bases are available in different gingival heights (L) and several coronal heights (h) for better crown fixation, e.g., when submerged. Uni-Bases with a coronal height greater than 3.5 mm can be manually shortened to this height. CAD libraries for Uni-Base and Uni-Base AN, including libraries for manually shortened variants, are available for software from exocad, 3Shape, and Dental Wings. Uni-Base Ti bases – straight with plastic burnout coping can also be used for the conventional method of superstructure fabrication by casting.

An overview of the Uni-Base bases is contained in this leaflet.