A team of LASAK experts has made a great effort to enhance the BioniQ® implant carrier with only one aim – to increase the safety and reliability of the implant system. The new implant carrier has been developed in such a way that damage to the implant‘s inner configuration or injury to the surrounding tissues during the implant insertion is avoided as much as possible. Protection of the inner structural elements of the implant ensures correct fixation of the restoration into the implant, and its long-term function. At the same time, setting safety limits for the new implant carrier significantly reduces the probability of excessive biomechanical stress in the surrounding bone tissue.

A team of LASAK experts has made a great effort to enhance the BioniQ® implant carrier with only one aim – to increase the safety and reliability of the implant system. The new implant carrier has been developed in such a way that damage to the implant‘s inner configuration or injury to the surrounding tissues during the implant insertion is avoided as much as possible. Protection of the inner structural elements of the implant ensures correct fixation of the restoration into the implant, and its long-term function. At the same time, setting safety limits for the new implant carrier significantly reduces the probability of excessive biomechanical stress in the surrounding bone tissue.

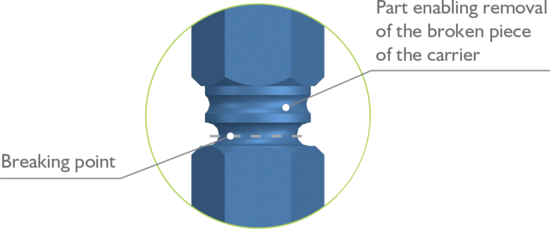

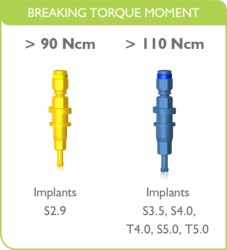

The new improved BioniQ® implant carrier is supplied with a pre-determined breaking point where – when the 90 Ncm insertion torque is exceeded for S2.9 implants and 110 Ncm insertion torque is exceeded for other implants (S4.0, T4.0, S5.0 and T5.0) – the upper part of the carrier will break off. The broken piece of the implant carrier can be easily removed from the insertion wrench/Unigrip, e.g. using tweezers. The insertion wrench/Unigrip can be attached to the remaining part of the implant carrier and the implant can be unscrewed from the bone using the reverse motion of the ratchet (anticlockwise motion). When handling the remaining part of the implant carrier, note that the part of it that is below the pre-determined breaking point is neither secured in the insertion wrench/Unigrip nor protected against excessively high torques.

Click here to download a leaflet.